Floating ball valves, trunnion ball valves and top entry ball valves

BÈTA Industrie is a specialist in ball valves for the on- and offshore and oil and gas industry. Our focus is on operated and manually operated Top Entry and Side Entry ball valves, forged Floating and Tap mounted ball valves. Our range of ball valves meets all the high and strict requirements of the high-risk industries. We combine our policy of high quality, design and development with an entrenched/contemporary vision of professional service and safety. All production processes comply with international safety and quality standards, in addition, all products are thoroughly tested and certified for quality assurance. API, ISO & PED accreditations and our knowledge ensure the highest custom quality.

Applications ball valves

The choice of ball valve type depends entirely on the application and the characteristics of the process in which the valve is to be implemented. For clean liquids, there are generally many different valves and materials to choose from. While for dirty liquids and high-risk applications, the choice is limited to a few types of ball valves and selected materials.

- Utility (water, air, nitrogen, hydraulic oils)

- Corrosive & Dirty(serious abrasive services in Sour, Sandy, Slurry, Pollution, Solidifying conditions

- High temperature (≤ 1000°C)

- Low temperature (-45°C - 0°C)

- Cryogenic (≥ -196 °C)

- High pressure (≤ 1,500 bar)

Ball valve / tap ball valve sizes

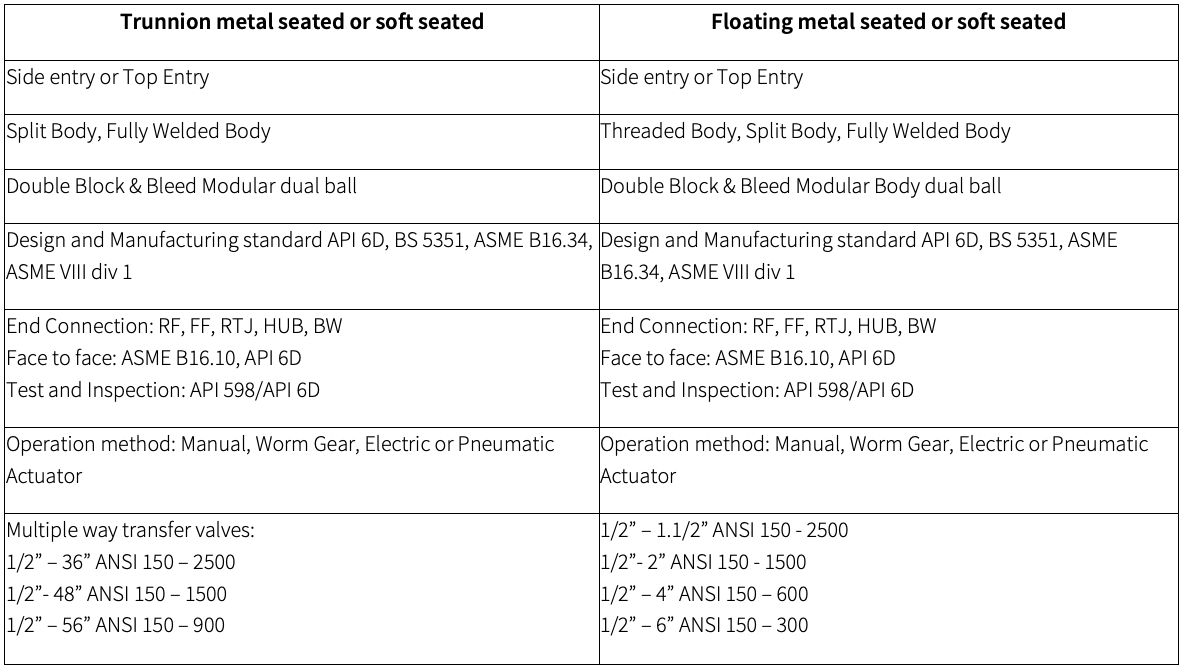

BÈTA industries delivery program includes the control and mixing of ball valves:

Engineering and manufacturing ball valve/tap ball valve

We are constantly innovating to offer a wider range of better ball valves. We can validate/check every step of engineering and production using advanced software (AutoCAD, Solid Works 3D), through Finite Element Analysis of loads, stresses, deformations and stress tests. We do this in accordance with the applicable international standards. In addition, we also have Top Nntry and Side Entry ball valves with split or fully welded housing, multi-way valves and modular or mono-flange double block & bleed valves from low to high pressure. All of these products are designed and manufactured to withstand and exceed high-risk industrial applications in high temperature cryogenics. Specific high-performance models are also available for corrosive and severe abrasive flows and function in sandy, slurry, fouling, scaling and solidification applications. We design and manufacture special products according to customer specific requirements and can offer solutions for the most critical processes:

- High temperature services (TCC or WCC treatment)

- Low temperature and cryogenic applications

- High temperature services

- Multiple way valves

- Fully welded valves

- A jacket valve

Normative References

Valves and ball valves can be designed, manufactured and tested according to the following international standards:

- American Petroleum Institute (API): API 6A, API 6D, 6DSS, 607, 598

- American Society of Mechanical Engineers (ASME): ASME B16.5, ASME B16.10, ASME B16.11, ASME B16.25, ASME B16.34, ASME B16.47, ASME B31.3, ASME B31.4, ASME B31.8, ASME IX, ASME VIII (Divisions 1 & 2)

- Manufacturers Standardization Society of the Valve and Fittings Industry, Inc. (MSS): MSS SP25, MSS SP44, MSS SP45, MSS SP53, MSS SP54, MSS SP55, MSS SP6, MSS SP61, MSS SP72, MSS SP82, MSS SP9

- British Standards Institute (BS): BS 1503, BS 1504, BS 1560, BS 2080, BS 4504, BS 5146, BS 5351, BS 6364, BS 6755, EN 558, EN1503, EN1626, EN1983, EN5211, EN12266, EN12516, EN12567 , EN12570, EN12627, EN12982

- International Organization for Standardization (ISO): ISO 5208, ISO 10423, ISO 10497, ISO 14313, ISO 14723, ISO 15156-3, ISO 15607, ISO 15609, ISO 15614-7, ISO 15848 (parts 1 & 2), ISO 17292

- American Society for Testing and Materials (ASTM): ASTM E94, ASTM E142, ASTM E165, ASTM E280, ASTM E446, ASTM 562, ASTM E709, ASTM G48\

- National Association of Corrosion Engineers-Corrosion Resistant (NACE): NACE MR0175, NACE MR0103, NACE TM0187, NACE TM0284

Material ball valves

Our valves for the oil and gas industry are available in the following materials. Materials not listed are available on request.

- Carbon stem ASTM A105, A105N

- ASTM A216 WCB, WCC

- ASTM A217 WC6, WC9, CW6, C12

- ASTM A350 LF2, LF3, LF6

- ASTM A352 LCB, LCC, LC3

- ASTM A694 F52, F60, F65

- Stainless steel ASTM A182 F11, F20, F22, F304/F304L, F316/F316L, F316H, F316Ti, F321, F347, F347H, F44

- Duplex ASTM A182 F5, F51, F52, F53, F55

- ASTM A182 F60, F65, F6A, F6B, F6NM F9, F91, FXM19

- ASTM A276/A479 304/304L, 316/316L, 316H, 316Ti, 321, 347, 347H, 904L

- ASTM A351 CK3MCuN, CA15, CF8, CF3, CF8M, CF3M, CG8M, CF8C

- ASTM A479 S31254, S31803, S20910, S32750, S32760, S41000, S41400, S41300, S17400

- ASTM A479 S31803, S32750, S32760, S20910, S41000, S41400, S41300, S17400&

- ASTM A739 B11, B22

- Nickel Alloys ASTM N08825, N06625, N04400, N08020, N07750, N07718, N08926, N07725

- Titanium ASTM B348 (Gr. 2 & 5), ASTM B381 F2

- Bronze ASTM B148 UNS C95500, C95800, C63200, ASTM B62

Certifications

Our ball valve engineering, manufacturing and testing processes are certified by a Quality Assurance program by recognized inspection bodies and continuously monitored in accordance with:

- ISO 9001:2008 for design, production and after sales of ball valves

- API Specification Q1 and Specification 6D

- Atex 94/9 / EC directive for equipment and protective systems intended for use in potentially explosive atmospheres

- PED 97/23/EC of the module H Pressure Equipment Directive

Each valve is identified by a serial number with relevant EN 10204 3.1 material certificate for retaining pressure parts and the pressure test report. A third party inspector witnesses every production activity, starting from raw material production to final testing and issuing a certificate according to EN 10201 3.2. Our ball valves are designed to meet all fire safety requirements including: BS6755 P.2, API 607, API6FA and ISO 10497 and Fugitive Emission according to ISO 15848/1. Qualification tests for the entire production chain are checked by independent inspectors.

Ball valve leak testing

Our production has its own in-house testing department, the following valve leak tests can be performed in-house by qualified and experienced personnel. Materials not listed are available on request.

- Hydrostatische shell & Seat-test;

- Lage druk gas-test (met lucht of stikstof) overeenkomstig bijlage B van API 6D, API 598, EN 12266-1 of de klant specifieke eisen;

- Hoge druk gas-test (met stikstof) overeenkomstig bijlage B van API 6D, API 598, EN 12266-1, BS 6364 of de klant specifieke eisen, van omgevingstemperatuur tot cryogene temperatuur tot -196 ° C

- Diffuse emissie gas-test (met Helium) volgens test ISO 15848/2

- Cavity relief-test

None destructive testing

TDe volgende Non Destructive Testing worden uitgevoerd door gekwalificeerd personeel, gecertificeerd volgens EN 473-ISO 9712 of SNT-TC-1A 2 LEVEL:

- MT (Magnetic Research)

- UT (ultrasonic examination)

- PT (Dye Penetrant Examination)

- RT (Radiographic Test)

- PMI (Positive Material Identification)

- hardness test

- Ferrite Test (from Fisher Feritscope FMP30)

Destructive testing

Thanks to a collaboration with Research Centers and Laboratories, the following Destructive Testing can also be performed in accordance with the customer and the specific requirements of the project:

- Mechanical and Drop test down to - 196 ° C

- Chemical analysis check

- Corrosion testing

- Micro examination via electronic microscope up to 500x magnifications

- Ferrite check at E562

- Hydrogen Initiated Cracking Test (HIC) & Sulfide Stress Corrosion Corrosion (SSCC)

Ball valves from BÈTA industrie

We are specialists in the field of ball valves and have already been able to supply our applications to many sectors. An extensive reference list of the valves supplied to end users, EPC Contractors and OEM in the Oil & Gas industry is available on request. Are you looking for a top quality ball valve? Our ball valves meet all requirements, at a competitive price and with a fast delivery time. For advice about our ball valves, please contact one of our specialists. You can reach us by phone on: +31 79 341 55 18 or you can simply contact us via the button below!

Contact us